Abstract

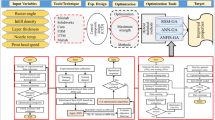

The capability to generate complex geometry features at tight tolerances and fine surface roughness is a key element in implementation of Creep Feed grinding process in specialist applications such as the aerospace manufacturing environment. Based on the analysis of 3D cutting forces, this paper proposes a novel method of predicting the profile deviations of tight geometrical features generated using Creep Feed grinding. In this application, there are several grinding passes made at varying depths providing an incremental geometrical change with the last cut generating the final complex feature. With repeatable results from coordinate measurements, both the radial and tangential forces can be gauged versus the accuracy of the ground features. The results of the tangential force were found more sensitive to the deviation of actual cut depth from the theoretical one. However, to make a more robust prediction on the profile deviation, its values were considered as a function of both force components. In addition, the power signals were obtained as these signals are also proportional to force and deviation measurements. Genetic programming (GP), an evolutionary programming technique, has been used to compute the prediction rules of part profile deviations based on the extracted radial and tangential force and correlated with the initial “gauging” methodology. It was found that using this technique, complex rules can be achieved and used online to dynamically control the geometrical accuracy of the ground features. The GP complex rules are based on the correlation between the measured forces and recorded deviation of the theoretical profile. The mathematical rules are generated from Darwinian evolutionary strategy which provides the mapping between different output classes. GP works from crossover recombination of different rules, and the best individual is evaluated in terms of the given best fitness value so far which closes on an optimal solution. Once the best rule has been generated, this can be further used independently or in combination with other close-to-best rules to control the evolution of output measures of machining processes. The best GP terminal sets will be realised in rule-based embedded coded systems which will finally be implemented into a real-time Simulink simulation. This realisation gives a view of how such a control regime can be utilised within an industrial capacity. Neural networks were also used for GP rule verification.

Similar content being viewed by others

References

Axinte D, Axinte M (2003) A multicriteria model for cutting fluid evaluation. Proc IME B J Eng Manuf 217(10):1341–1353

Chen X, Rowe WB (1999) Modelling surface roughness improvement in grinding. Proc IME B J Eng Manuf 213(1):93–96

Griffin J, Chen X (2009) Characteristics of the Acoustic Emission during Horizontal Single Grit Scratch Tests – Part 2 Classification and Grinding Tests. International Journal Abrasive Technologies- Special Issue on: Micro/Meso Mechanical Manufacturing (M4 Process). Vol. 1, No 4

Griffin J, Chen X (2009) Multiple classification of the acoustic emission signals extracted during burn and chatter anomalies using genetic programming. Int J Adv Manuf Technol 45(11–12):1152–1168

Hekman KA, Liang SY (1998) Feedrate optimization and DOC control for productivity and parallelism in grinding. Mechatronics 9:447–462

Hekman KA, Liang SY (1998) Flatness control in grinding by depth of cut manipulation. Mechatronics 8(4):323–335

Howard D, Roberts SC et al (1999) Target detection in SAR imagery by genetic programming. Adv Eng Softw 30(5):303–311

Howard D, Roberts SC et al (1999) Evolution of ship detectors for satellite SAR imagery. Genet Program 1598:135–148

Howard D, Roberts SC et al (2006) Pragmatic genetic programming strategy for the problem of vehicle detection in airborne reconnaissance. Pattern Recogn Lett 27(11):1275–1288

Kurfess TR, Whitney DE (1992) Predictive control of a robotic grinding system. J Eng Ind 114(4):412–420

McCulloch WS, Pitts WH (1943) A logical calculis of the ideas immanent in nervous activity. Bull Math Biophys 5:115–133

Ozel T, Karpat Y (2005) Predictive modelling of surface roughness and tool wear in hard turning using regression and neural networks. Int J Mach Tools Manuf 45:467–479

Razavi HA, Kurfess TR et al (2001) Force control grinding of gamma titanium aluminide. Int J Mach Tools Manuf 43:185–191

Rumelhart DD, Hinton GE, Williams RJ (1986) Learning representations by back-propagating errors. Nature 323:533–536

Sick, B. (2002) On-line and indirect tool wear monitoring in turning with artificial neural networks: a review of more than a decade of research. Mechanical Systems and Signal Processing 16, pp 487–546

Silva, S. (2004) A genetic programming toolbox for Matlab—version 2. ECOS—Evolutionary and Complex Systems Group, University of Coimbra, Portugal, http://gplab.sourceforge.net/

Silva, S. and Y. T. Tseng. (2005) Classification of seafloor habitats using genetic programming. GECCO '05. Washington

Srivastava AK, Elbestawi MA (1995) Control strategy for multipass robotic grinding. Int J Robot Autom 10(3):114–119

Yoo, S. M. (1990) Computer simulation of the flexible disk grinding process: flat surface control using variable vertical feed speed. Symposium on Monitoring and Control for Manufacturing Processes. ASME WAM PED 44: 123–32

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Griffin, J. The prediction of profile deviations when Creep Feed grinding complex geometrical features by use of neural networks and genetic programming with real-time simulation. Int J Adv Manuf Technol 74, 1–16 (2014). https://doi.org/10.1007/s00170-014-5829-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-5829-0